Longquan Swords: The Master Swordsmiths of Longquan, China

The first master swordsmith of Longquan was thought to be Master Ou. When he settled in the mountains of Longquan, China in the Zhejiang Province over 2,500 years ago, rumors spread that the waters of the nearby river contained unique minerals that reacted with the blade’s metal when quenched to enhance its resilience and strength. The Longquan swords that Master Ou forged became the basis for other swordsmiths throughout China, and soon their knowledge passed to Japanese smiths on the nearby archipelago.

The Process

The ancient method of Chinese and Japanese swordsmithing begins with two types of metal. A softer steel core is enveloped in a harder outer jacket and the two work in tandem to create a strong, flexible blade that can hold a superior edge. The Japanese took the Chinese method of Longquan swordmaking and improved on it to create highly durable samurai swords. Their traditions continue today.

The Metal

The raw metal used when forging swords in Japan is called tamahagane. This is a special steel made up of iron sand and charcoal. Smiths heat and reheat it to remove impurities and choose the best pieces of steel to use for their swords.

Smelting

Once the tamahagane has been determined pure enough, the smiths start heating and folding the steel to remove even more impurities. Many blades have thousands of layers and develop a dense mesh structure that results in beautiful designs in addition to their increased durability.

Shaping & Quenching

A master smith will have a shape in mind for their sword. Whether it’s meant to be a katana or a nodachi, the smith will hammer the blade into shape. When he is satisfied with the result, the sword is ready to be quenched.

If the steel is strong and the smith is satisfied, it is time to drill holes in the tang of the blade so it can be attached to a hilt with bamboo mekugi pins. The sword is then polished through a long, multi-step process to ensure the hamon line shines and the edge is sharp.

Sharing Techniques

As sword making developed in feudal Japan, master smiths shared techniques back and forth with Chinese and Longquan swordsmiths, strengthening their methods and the resulting weapons. Most authentic smithies still use the exact same methods their great great forefathers used hundreds of years ago.

Ancient Techniques Made New

Even in today’s modern age, swordsmiths in both Longquan, China and throughout Japan use these same methods to create works of art. They carefully pass down the knowledge of their cultural heritage to keep this history alive.

The swordsmiths in Longquan currently operate about 100 workshops and factories that produce thousands of swords for everything from movies and television to private collectors and enthusiastic martial arts practitioners.

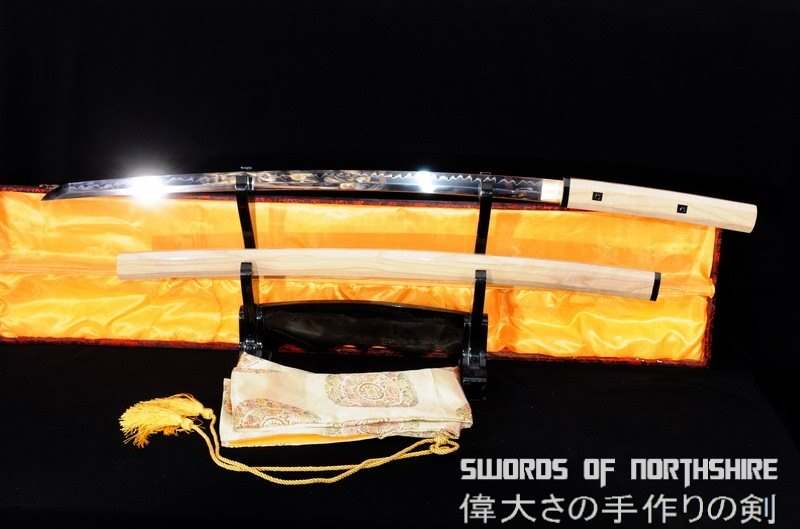

Swords Straight from Longquan

Swords of Northshire is proud to be a part of the respected heritage of sword making in Longquan, China. We supply Longquan swords made to order straight from the master smiths to ensure the quality and craftsmanship behind each weapon. When you choose to shop our collection of premium handcrafted swords, you too are participating in a proud tradition.

Order from our selection today to find traditional Chinese weapons, ninja swords, and even replica swords from popular media.

Best Sellers

- Regular Price

- from $199.99

- Sale Price

- from $199.99

- Regular Price

-

- Unit Price

- per

- Regular Price

- from $299.99

- Sale Price

- from $299.99

- Regular Price

-

$0.00

- Unit Price

- per

- Regular Price

- from $619.99

- Sale Price

- from $619.99

- Regular Price

-

- Unit Price

- per

- Regular Price

- from $179.99

- Sale Price

- from $179.99

- Regular Price

-

- Unit Price

- per

- Regular Price

- from $319.99

- Sale Price

- from $319.99

- Regular Price

-

- Unit Price

- per

- Regular Price

- from $339.99

- Sale Price

- from $339.99

- Regular Price

-

- Unit Price

- per

- Regular Price

- from $219.99

- Sale Price

- from $219.99

- Regular Price

-

- Unit Price

- per

- Regular Price

- from $199.99

- Sale Price

- from $199.99

- Regular Price

-

- Unit Price

- per

- Regular Price

- from $364.99

- Sale Price

- from $364.99

- Regular Price

-

- Unit Price

- per

- Regular Price

- from $479.99

- Sale Price

- from $479.99

- Regular Price

-

$0.00

- Unit Price

- per